Production, Parts 3D Printer

Larger-size SLA 3D printer

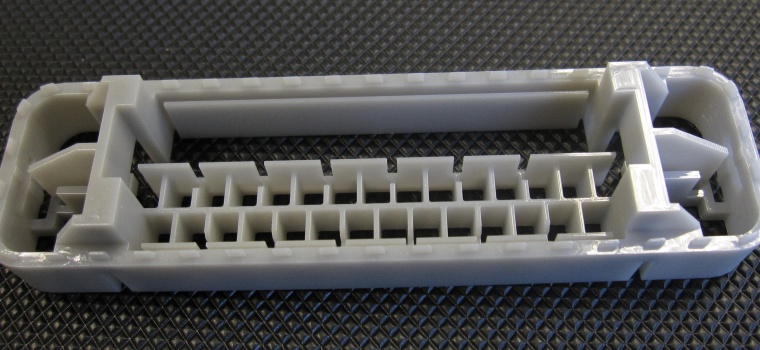

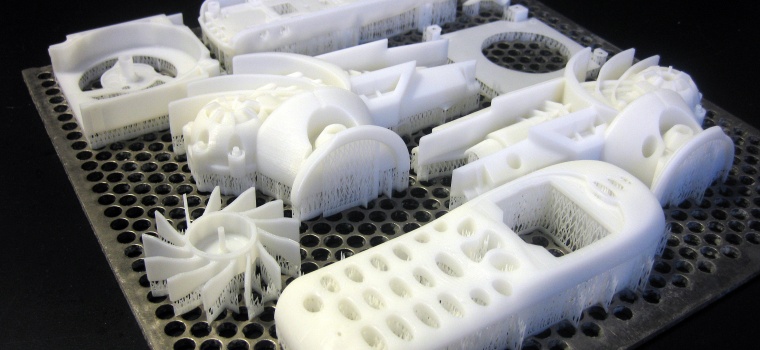

The ProJet 7000 uses stereolithography technology to create accurate and perfectly formed 3D printed parts and prototypes.

The ProJet 7000 is available in 3 models, SD, HD and MP, with the largest build platform delivering 15 x 15 x 10 inches (380 x 380 x 250 mm) of available build space.

Used by aerospace, automotive, heavy equipment, consumer product and industrial designers, with the ProJet 7000 MP being particularly popular with medical device manufacturers, these systems offer a wide range of material choices. Materials closely match that of their traditional alternatives with ABS-like properties with the VisiJet SL Black, resistance to temperatures as high as 130oC with the VisiJet SL HiTemp, and materials that allow direct creation of casting patterns for foundries and investment casting facilities. VisiJet SL Clear is also USP Class VI certified, making it ideal for medical product manufacturing, especially in mass custom manufacturing.

These printers delivery an accuracy of 0.001 – 0.002 inch per inch of part dimension and very fast printing speeds. Each printer is delivered with the 3D Manage software that enables easy build job setup, build optimization tools, parts stacking and nesting, and job monitoring.

Request A Quote:

Benefits:

- Large build size of up to 15 x 15 x 10 inches (380 x 380 x 250 mm)

- Wide choice of materials

- USP Class VI certified material available

- Accuracy of up to 0.001 inches per inch of part dimension

- Super-fast stereolithography technology

Case Studies:

- Fujikon Takes Fast-Moving World of Headset Products to New Heights with 3D Systems’ SLA 3D Printing Technology

- 3D Printing Makes Thinkers into Doers

- EGR Gets Parts Made Quickly by Quickparts®

- Realize Inc. Puts ProJet® 7000 Through Its Paces

- 3D Medical Application Center Delivers Custom Implants Faster with Geomagic Freeform