Reverse Engineering Services

We help individuals, companies, and entrepreneurs bring their vision to life with cutting-edge 3D scanning technology and advanced reverse engineering workflows.

Whether native CAD never existed, your design files are being held hostage, or you simply find a component or shape that you would like to incorporate into a larger assembly you are designing; we have the reverse engineering tools and workflows to accomplish your goals – either by doing the work as a service or selling and training you on the tools we utilize.

Did you know?

F16 planes were created before widespread adoption of 3D CAD software

We have had clients need us to scan parts they had manufactured overseas as the manufacturer refused to release the files the client paid for

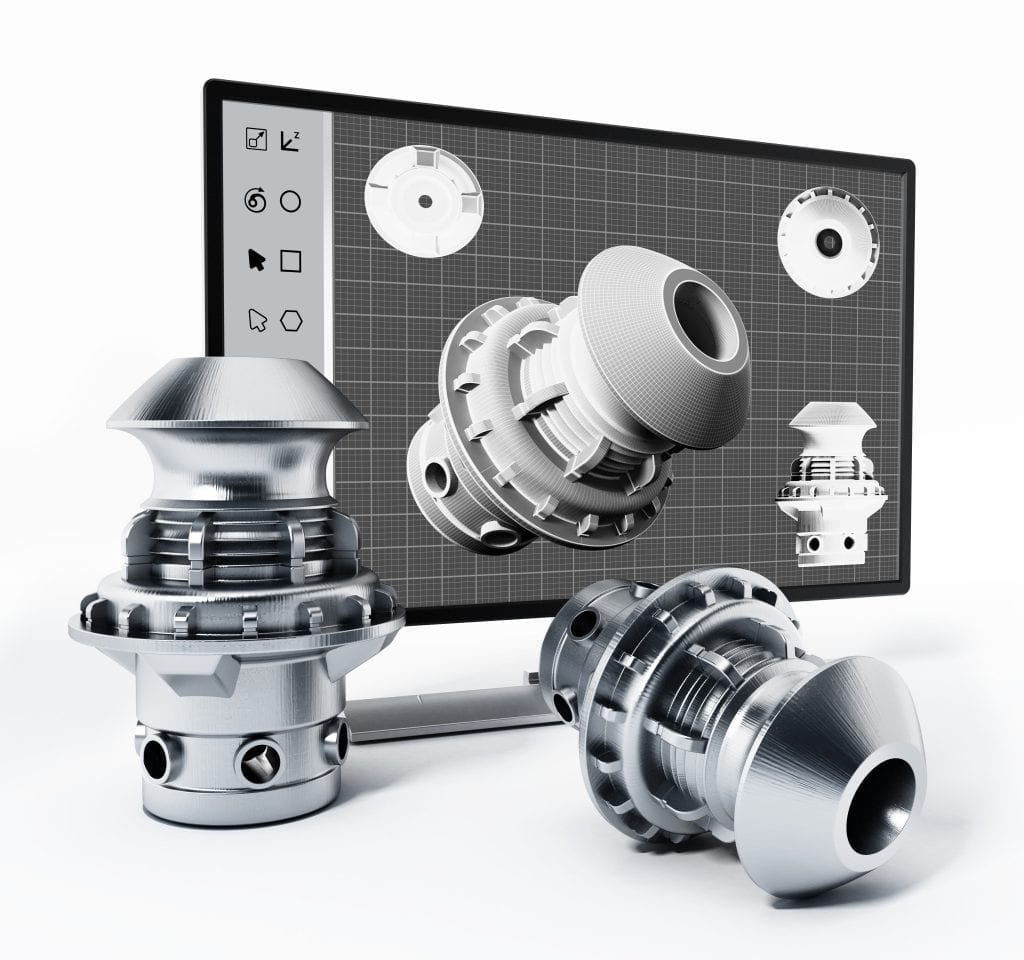

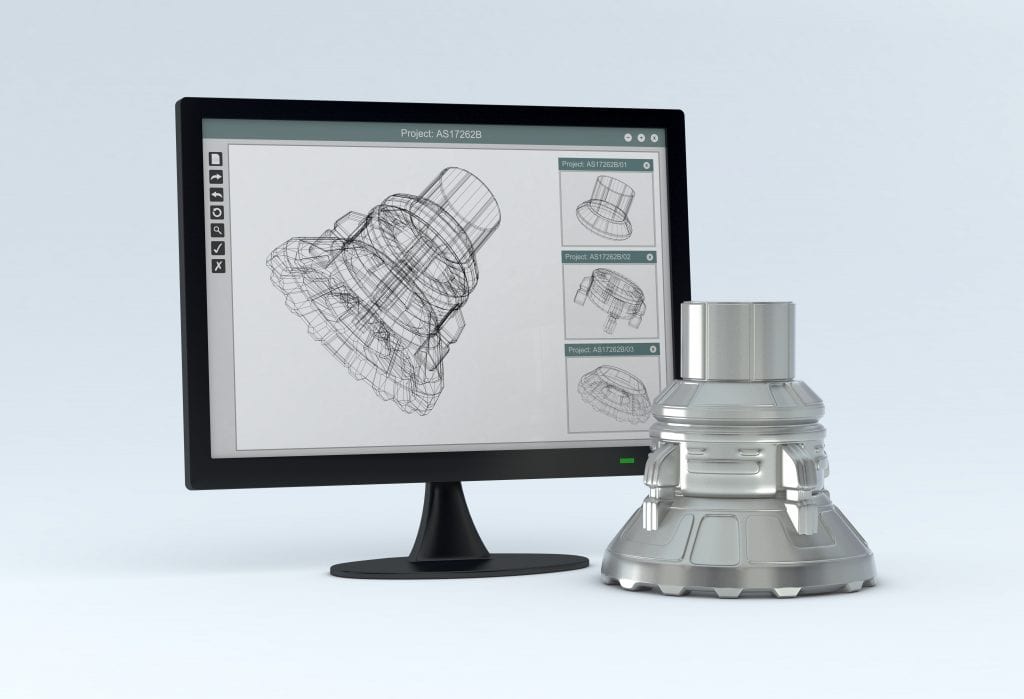

Scan Directly To CAD Files

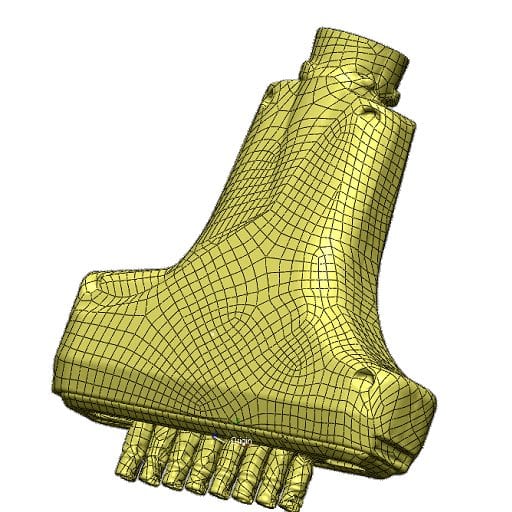

Auto Surfaced Solid VS Fully Feature Based Solid

|

|

| Less expensive – Less time to produce | More expensive – Fully reverse engineered |

| Many surfaces stitched together to make a solid | Faces that correspond with the geometry of the part |

| Less precise due to software ‘wrapping’ surfaces around scan data | Extremely precise |

| Difficult to pull dimensions from | Easily identifiable dimensions |

| Can make extruded cuts into body | Can perform any of the functions you are able to perform on a native CAD file on the part |

| **Can export as: .stp, .stl, .igs | **Can export as: .stp, .stl, .igs, .sldprt (solidworks), .prt (creo), .ipt |